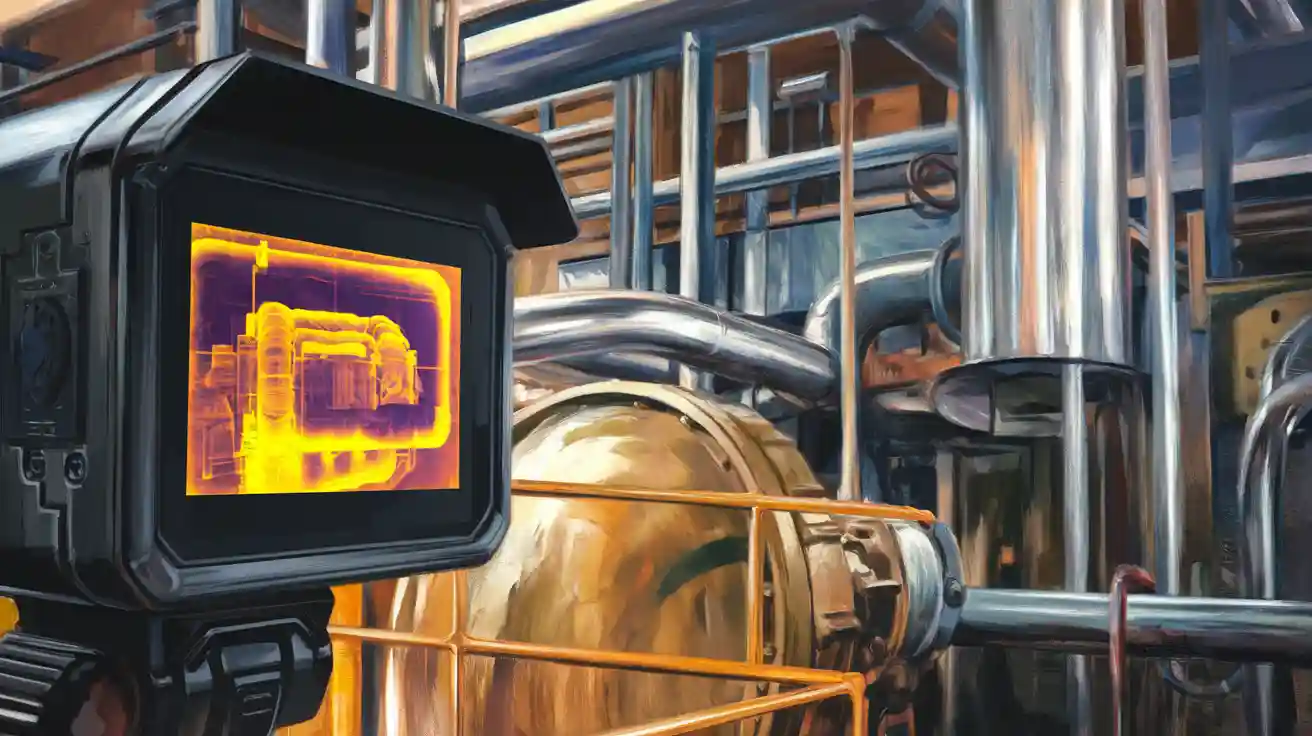

You need a tool you can trust to find heat. The Verytek ATR1280 HD Online Thermal Camera is an excellent choice for your needs. Its HD infrared thermal imaging provides clear pictures, and with its electric focusing feature, you can achieve the best view quickly. Real-time monitoring allows you to observe every change as it happens. The infrared sensor checks temperatures from -20°C to +550°C, ensuring you get precise measurements with an accuracy of ±2°C or ±2% of readings. See more details in the table below:

Feature | Specification |

|---|---|

Resolution | 1280 x 1024 |

Measurement Range | -20°C to +550°C |

Thermal Sensitivity (NETD) | <50mK |

Measurement Accuracy | ±2°C or ±2% of readings |

With its advanced infrared thermal imaging, robust build, and straightforward setup, this industrial thermal camera is a smart pick for your industrial needs.

Key Takeaways

The Verytek ATR1280 HD Online Thermal Camera gives clear infrared pictures. It helps you find heat problems fast and correctly. Real-time monitoring lets you see temperature changes right away. This keeps people safe and stops possible fires at work. Using this camera can cut down on repair costs. It finds problems early, so you can fix them before they get worse. This also helps your equipment last longer. The camera is strong and works in many temperatures. It is good for many types of industrial jobs. It works well even in hard places. Advanced features like electric focusing help you use it better. Many measurement tools let you make smart choices and improve your work.

Importance of Reliable Heat Detection

Safety and Efficiency

It is important to find heat problems early. This keeps everyone safe at work. Watching temperatures helps you spot fire risks fast. An industrial thermal camera lets you see heat changes right away. You can stop fires before they start. This protects your team from danger. Fire prevention monitoring helps you check for hot machines or electrical faults. If you find a problem early, you can fix it. This stops fires and keeps production going.

Thermal cameras show you where the problem is. You can act quickly when you see a fault. This keeps your machines working well. You spend less money on emergency repairs. Your machines last longer. Temperature monitoring helps you plan repairs when work is slow. You do not need to shut down everything. Your work keeps moving.

Tip: Use temperature monitoring at night. You can find fire risks even when it is dark.

Here is a table that shows how industrial thermal cameras help you:

Benefit | Description |

|---|---|

Early Detection | Finds hot spots and temperature changes before big problems happen. |

Optimizing Repairs | Lets you fix things when work is slow, so you avoid stopping work. |

Lowering Maintenance Costs | Saves money by stopping emergency repairs and extra replacements. |

Extending Equipment Lifespan | Keeps machines working longer and helps them run better. |

Risks of Poor Monitoring

If you do not watch temperatures, you face many dangers. You might miss signs of fire or other safety problems. It is harder to find faults. You may not see a problem until it causes damage. Without fire prevention monitoring, small problems can become big emergencies. You could lose machines or have long breaks in work.

Bad monitoring means you cannot act fast when there is a fire or danger. You may not see a problem in time to fix it. This can cost you money and put people at risk. It is harder to find where the problem is. You may not find the fault before it is too late. Good temperature monitoring helps you avoid these dangers and keeps your workplace safe.

Industrial Thermal Camera Features

HD Infrared Thermal Imaging

You need clear pictures to find heat problems fast. The ATR1280 HD Online industrial thermal camera shows sharp infrared images. Its high resolution is 1280 x 1024. You can see small details and tiny temperature changes. The infrared sensor finds heat from machines, wires, and surfaces. This thermal imaging camera helps you spot hot spots before they get worse.

The camera uses advanced infrared technology. You get correct readings even in tough places. Electric focusing lets you zoom in on the area you want. You do not miss any important details. The wide temperature range from -20°C to +550°C means you can use the camera for many jobs. You can trust the infrared thermal imaging to give you the right information every time.

Feature | |

|---|---|

Infrared Resolution | 1280×1024 |

Thermal Sensitivity | <50mK |

Measurement Range | -20℃ to +550℃ |

Measurement Accuracy | ±2°C or ±2% of readings |

Measurement Tools | 12 points, lines, areas, isotherm |

Communication Interface | Gigabit network interface |

Real-Time Monitoring

You want to see changes as they happen. The ATR1280 thermal imaging camera gives you real-time monitoring. You can watch heat patterns move and change. This helps you make quick choices and keep your workplace safe.

Note: Real-time imaging helps you find problems before they get worse.

Here are some ways real-time monitoring helps you:

Temperature Monitoring: You see heat changes right away. This helps you keep machines working well.

Equipment Maintenance: You find strange heat fast. You can fix problems before they stop work.

Energy Efficiency: You spot heat loss and save energy.

Safety Enhancement: You see fire risks early and protect your team.

Quality Control: You check for defects using detailed infrared thermal imaging.

Process Optimization: You use data to improve how things work.

You get instant feedback with real-time monitoring. You can act quickly and keep everything running smoothly.

Advanced Measurement Tools

You need tools that make your job easier. The ATR1280 industrial thermal camera gives you many choices. You can set up to 12 points, lines, and areas for measurement. Isotherm settings help you see temperature zones clearly. The infrared thermal imaging camera lets you check different parts of a machine or system at the same time.

You can use digital zoom to look closer at any spot. The camera offers 18 color palettes, like black-hot, white-hot, iron red, and rainbow. You pick the best view for your needs. These features help you find problems faster and make better choices.

Feature | Description |

|---|---|

Color Palettes | 18 choices, including black-hot, white-hot, rainbow |

Digital Zoom | 1.0~8.0 continuous zoom (step size: 0.1) |

You can connect the camera to your network using the Gigabit interface. This makes it easy to use the camera with other systems. You get fast data transfer and smooth real-time monitoring.

Robust Design

You need a camera that works in tough places. The ATR1280 thermal imaging camera has a strong build. It works well in temperatures from -20°C to +60°C. The infrared sensor keeps working even in hot or cold conditions. The camera uses a temperature compensation algorithm. This means you get correct readings no matter where you use it.

The electric focusing scheme gives you stable operation and fast response. You can count on the camera in busy industrial settings. The high-resolution infrared thermal imaging helps you see every detail. You get the right information to keep your workplace safe.

Feature | Description |

|---|---|

Wide Operating Temperature Range | Works from -20°C to +60°C in many industrial conditions |

High-Resolution Imaging | 1280 x 1024 infrared images for clear detail |

Advanced Temperature Measurement | Measures from -20°C to +550°C for high-temperature jobs |

Temperature Compensation | Adjusts for environment to keep measurements correct |

Electric Focusing Scheme | Stable and fast operation for busy settings |

The ATR1280 industrial thermal camera gives you reliable infrared thermal imaging, real-time monitoring, and strong performance. You can use it for many jobs and trust it to deliver results.

How ATR1280 Stands Out

Unique Technology

You want a camera that helps you do better work. The ATR1280 has special features that make it different from other cameras. It gives you high-definition imaging, so you see more details in every infrared picture. The resolution is 1280×1024, which helps you notice small temperature changes. The camera also sends data very fast. The Gigabit network interface lets you get real-time temperature data quickly. This means you can act fast if you spot a problem. The advanced temperature measurement tools help you study heat using professional software. You can use these tools for research or automation jobs.

Here is a table that shows what makes the ATR1280 special:

Unique Technology | Description |

|---|---|

High-definition imaging | Gives you clearer and more detailed infrared thermal images with a resolution of 1280×1024. |

High-speed data transmission | Sends temperature data in real time using a Gigabit network interface. |

Has professional software for accurate temperature analysis in many fields. |

Tip: Use the electric focusing lens to make your infrared images sharp every time.

Comparison to Other Cameras

You might wonder how the ATR1280 is different from other cameras. Many cameras only give you basic infrared imaging. The ATR1280 gives you more features. It has a wide temperature range from -20° C to 550° C. The pixel pitch is 12μ M, so you see fine details in every image. The frame rate is 15Hz, which lets you watch heat changes as they happen. The electric focusing lens helps you change the view quickly. Most cameras use manual lenses, but the ATR1280 lets you focus faster and easier.

Here is a table that highlights the main features:

Feature | ATR1280 |

|---|---|

Resolution | 1280×1024 |

Temperature Range | -20° C to 550° C |

Pixel Pitch | 12μ M |

Frame Rate | 15Hz |

Lens Type | Electric focusing lens |

You will notice the difference when you use the ATR1280. The camera gives you sharper infrared images, faster data, and more ways to measure heat. You get a reliable industrial thermal camera that helps you do your job better.

Applications

Industrial Automation

You can use the ATR1280 for many jobs in factories. This industrial thermal camera helps you find heat problems fast. You get clear infrared pictures that show hot spots. You can see issues before machines break down. Many companies use this technology to keep things safe and working well.

Here are some places where you can use it:

Application Area |

|---|

Power Utilities |

Oil, Gas and Petrochemical Industries |

House Inspection |

PCB Inspection |

You can check power lines and transformers with the camera. You can look at oil and gas equipment for heat problems. In house inspection, you find heat leaks or bad wires. For PCB inspection, you see if parts get too hot. The infrared sensor gives quick and correct results. You can fix things before small problems get worse.

Tip: Use the camera often to help your equipment last longer.

Research and Education

You can use the ATR1280 in science labs and classrooms. The high-resolution infrared pictures help you study how heat moves. You can watch temperature changes as they happen. This helps you learn more about science and engineering.

Teachers use the camera to show students how heat spreads. Students can see what heat does to different things. In research, you can measure temperature changes during tests. The camera’s advanced infrared features help you collect data fast and easily.

You can also use the camera to stop problems before they start. You find hidden heat issues before things break. This keeps your lab or classroom safe. The ATR1280 gives you tools to learn and explore infrared technology.

You need a thermal camera that always works well. The ATR1280 shows clear infrared pictures and gives you fast results. It is strong and works in many places. You can use it in a factory, lab, or classroom. Its special features help you find heat problems fast.

HD resolution and electric focusing help you do your job.

Real-time monitoring helps keep everyone safe at work.

The wide temperature range lets you use it for many jobs.

Pick the ATR1280 if you want heat detection you can trust for your work.

FAQ

How do you set up the ATR1280 thermal camera?

You plug the camera into your network with the Gigabit interface. The software helps you set the focus and pick where to measure. Setting up the camera is quick and easy.

What temperature range can you measure with this camera?

The camera checks temperatures from -20°C up to +550°C. This lets you test many machines and surfaces.

Can you use the ATR1280 for real-time monitoring?

Yes, you can see heat changes right away. The camera shows live infrared pictures on your computer for fast updates.

What industries use the ATR1280 thermal camera?

Industry | Example Use |

|---|---|

Manufacturing | Machine safety checks |

Research | Lab experiments |

Education | Science demonstrations |

Utilities | Power line inspections |

How do you focus the camera for clear images?

Tip: Try the electric focusing feature. Click a button in the software to move the lens. You will get clear infrared pictures every time.

See Also

Vanadium Oxide Thermal Cameras: Essential Tools for Rescue

The Importance of Thermal Imaging Cameras in 2025

Utilizing Thermal Imaging Cameras for 2025 Search and Rescue