You use a drone thermal camera to find hidden problems in power lines. This device has a thermal imaging camera that shows heat patterns. It helps you see faults you cannot see with your eyes. Reliable power delivery is important for everyone. Utility companies, like Atlantic City Electric, use this technology for safer checks. With thermal imaging, you can find broken wires or hot spots on the line. This technology helps you work faster and get better data. Many experts trust thermal imaging cameras, Security Thermal Camera, and other new imaging tools to keep power working.

Utility companies started using drone thermal cameras for power line checks in the last five years.

Atlantic City Electric has used drones for equipment checks since 2018, showing more people are using this technology.

Key Takeaways

Drone thermal cameras help find hidden problems fast and safely. They show heat patterns that point out issues you cannot see.

Using drones for inspections saves both time and money. Checks that took days now only take hours, which lowers costs a lot.

Drones keep workers safe by letting them check power lines from far away. This lowers the chance of accidents near high-voltage gear.

Good thermal images from drones help spot small problems early. Finding issues early stops expensive repairs and power outages.

Using more sensors, like RGB cameras and LiDAR, improves data collection. This gives a full view of power line conditions in one flight.

Drone Thermal Camera Technology

Thermal Imaging Basics

Thermal imaging lets you see heat that your eyes cannot. This helps you find problems before they get worse.

You can find hot spots on power lines.

The camera sees infrared light and makes pictures from it.

These pictures use colors to show how hot things are.

You can check live equipment without touching it, which keeps you safe.

Thermal imaging cameras are very sensitive. They can find tiny temperature changes, even as small as 0.05°C. This helps you spot problems early and keep power lines working well.

Tip: Thermal imaging helps you check power lines fast and safely. You do not need to climb poles or go near dangerous equipment.

UAV Sensors and Modules

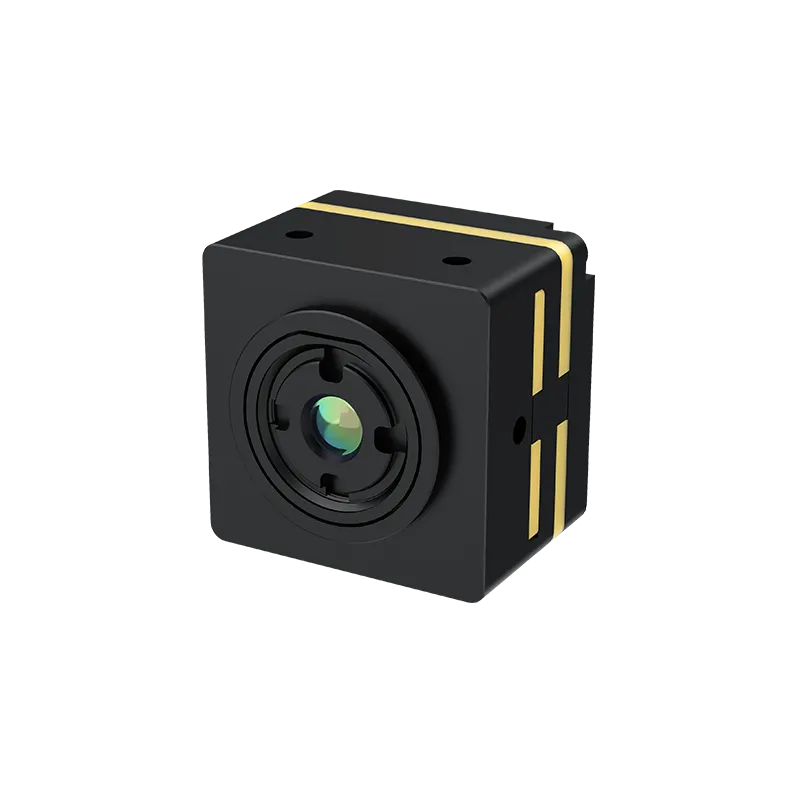

Drones can use special sensors and modules for better checks. Lightweight gimbal thermal modules help drones carry strong cameras. Companies like Verytek make these modules with good research. You get clear pictures and strong performance.

Drones can carry more than thermal cameras. You can add RGB cameras and LiDAR sensors for more data.

RGB cameras take normal pictures of power lines.

LiDAR sensors use lasers to map and measure things.

Using these sensors together gives you lots of data at once.

Thermal sensitivity matters for infrared cameras. A camera with 50mK sensitivity finds temperature changes as small as 0.05°C. This helps you see tiny heat changes on equipment.

Integration with Drones

Drone technology makes checks faster and safer. Drones fly over power lines and use cameras to collect data. Workers do not need to go into risky places.

Drones with thermal, RGB, and LiDAR sensors can map plants and find problems easily.

Using drones saves money and keeps workers safe instead of using helicopters.

Drones can get LiDAR, RGB, and thermal images in one trip.

Drones give you lots of details for power line checks. You can see heat, find faults, and plan repairs before things get worse. Drone technology helps you work smarter and keep power running.

Inspection Benefits

Safety and Efficiency

Checking power lines can be dangerous. Drones with thermal cameras help keep you safe. You do not have to climb tall poles. You do not need to work near live wires. Drones fly over power lines and collect data from far away. This way, you avoid accidents and stay out of danger.

Safety Tip: Use drones to watch power lines. This keeps you away from high-voltage equipment.

Line workers get hurt on the job every year. This job is one of the most dangerous. Workers miss more days from injuries than most other jobs. Using drones lowers these risks and helps protect you.

Drones also make inspections faster. You can check big areas in hours, not days. You save time and keep your team safe.

Data Quality

You need good data to find problems early. Drones with thermal cameras give you clear heat pictures. You can see hot spots and faults that your eyes miss. Thermal imaging shows where equipment gets too hot. You use this data to plan repairs before things break.

Drones can carry many sensors for checks. You get thermal, RGB, and LiDAR data in one flight. This gives you a full view of the power lines. You can look for heat changes, broken wires, and other problems. You get good results every time you check.

Note: Good images help you find small problems before they get worse.

You can trust drone data. You get detailed heat images and clear photos each time. This helps you make smart choices and keep power working well.

Cost Savings

You want to save money when you inspect power lines. Drones help you spend less by working faster and needing fewer people. You do not need helicopters or big crews. Drones finish jobs quickly and use less gear.

Here is a table that shows how much time drones save:

Inspection Type | Manual Inspection Time | Drone Inspection Time | Time Savings |

|---|---|---|---|

High-Voltage Power Line | 500 hours (20 days) | 2-4 hours | |

100 MW Solar Farm | 2500 hours (100 days) | 10-20 hours | Up to 99% faster |

You also save money on inspection costs:

Inspection Type | Manual Inspection Cost | Drone Inspection Cost | Time Savings |

|---|---|---|---|

High-Voltage Power Line | $10,000 per day | $2,000 per day | 80% faster |

You spend less on workers and equipment with drones. You finish checks faster and keep costs low. Drones with thermal cameras help you find heat problems early. This helps you avoid expensive repairs.

Drones help you get better results and spend less money.

You get safer, quicker, and better inspections with drones. You improve checks and save money. Drones with thermal cameras make power line inspection easier and smarter.

Key Features of Drone Thermal Cameras

Resolution and Sensitivity

You need clear pictures to check power lines. Good cameras show small heat changes. High resolution helps you see tiny details. Most drones use cameras with at least 640 × 512 pixels. This makes images sharp and easy to read. Sensitivity is important too. A camera with 50mK sensitivity finds small heat spots. You can spot problems before they get worse.

Requirement | Specification |

|---|---|

Minimum Resolution | 640 × 512 pixels |

Thermal Sensitivity | 50mK or better |

Tip: Clear thermal images help you find hidden problems and keep power lines safe.

Flight Time and Range

Drones with long flight time work longer without stopping. They can check more power lines in one trip. A wide range lets drones reach far places. You get good thermal images over big areas. Drones can go back and take more pictures if needed.

Feature | Benefit |

|---|---|

Extended Flight Time | Longer checks without stopping, covering more area |

Enhanced Range | Checks in tough places, making sure you see everything |

Good thermal pictures over long distances, helping you find problems | |

Intelligent Re-Shooting | Drones can take more pictures of important spots |

Drones check power lines faster than old ways.

More checks help you find problems early.

You stay safe by not going near dangerous places.

Data Transmission

You need fast data to see problems right away. Drones send thermal images to your team as they fly. You see heat patterns on your screen in real time. Quick data helps you make choices fast. You can fix problems sooner and keep power on.

Software Integration

Smart software makes checks easier. It finds faults by itself. You see problems as soon as they happen. The software talks to other systems to keep your team updated. Geo-referenced images show where the problem is, so you can fix it fast.

Feature | Benefit |

|---|---|

Automated defect detection | Finds problems quickly and correctly |

Real-time data monitoring | Lets you act fast when you see a problem |

Integration with asset management | Keeps your team in the loop |

Geo-referenced images | Shows where to fix things for your team |

One company checked over 675,000 images and did more inspections.

Smart software helped fix problems 70% faster.

Power Line Inspection Process

Planning and Compliance

You always plan before you start an inspection. You pick the best routes and tell your team what to do. You must follow rules to keep everyone safe and follow the law. Here is a table that lists the main rules for drone power line checks:

Regulatory Requirement | Description |

|---|---|

FAA Regulations | You must follow Federal Aviation Administration rules, especially for BVLOS inspections. |

Data Sovereignty | Companies must keep drone data in approved places to follow local laws. |

Operational Risk Assessments | You need to check risks to get approval for big drone jobs, especially for BVLOS. |

You look at these rules before flying. This keeps your work safe and your data protected.

Automated Drone Flights

Automated drone flights help you check big areas fast. You set up drones to fly along power lines by themselves. This makes sure your pictures are always the same. Drones use GPS and terrain-following to avoid mistakes. You can check up to 15,000 square kilometers with remote flights. You spend less time between flights and get better results. Automated flights mean fewer people need to be on-site, which is safer.

Tip: Automated drone flights help you check more lines with less work.

Data Collection and Analysis

Drones take pictures and videos during every check. You use infrared imaging to find hot spots and corona effects. Special software helps you look at thermal images and spot important things. Thermal imaging uses colors to show where things are hot.

Infrared data helps you find overheating and corona effects.

Software looks at the images for important details.

Color palettes in thermal images make hot spots easy to see.

These tools help you know the condition of your power lines and plan repairs.

Reporting

You make clear reports after each check. Good reports help your team fix problems quickly. Here are some best ways to report:

Executive summary — only three main points

Critical findings — things that need fast action

Deviation maps — pictures that show changes

Trending analysis — shows how things change over time

Recommended actions — steps to fix problems

Supporting evidence — photos, measurements, and locations

Platforms like Bentley AssetWise and DroneDeploy help you make reports automatically. You can link pictures to repair jobs and share them with your team. This makes your inspection work easier and better.

Challenges and Solutions

Weather and Environment

When you use drones for thermal imaging, weather can cause problems. Strong winds can make drones shake in the air. Rain, snow, or fog can make images less clear. Very hot or cold weather can hurt the drone or its sensors. Bright sunlight can make it hard to see heat pictures. Bad weather can slow down your work or make it tough to get good data. Always check the weather before flying your drone. Many drones now have sensors that help them stay steady in bad weather.

Tip: Try to fly on clear days for the best images.

Regulations

You have to follow many rules when flying drones for power line checks. These rules help keep everyone safe. Here is a table with some main rule problems:

Regulatory Challenge | Description |

|---|---|

FAA Regulations | You must follow Part 107 rules for drone operations. |

Airspace Coordination | You need to plan flights near airports and talk to air traffic control. |

NERC Standards | You must have strong inspection programs for power lines. |

State and Local Regulations | You may face extra rules about privacy, the environment, or local flying limits. |

Always check the newest rules before you start your drone check.

Data Interpretation

Thermal imaging gives you lots of information, but you need to know how to read it. Drones collect high-quality images and LiDAR data for asset checks. Some drones can find faults and send images to your team right away. Smart sensors and software help you spot risks fast. Real-time images let you act quickly if you see a problem. Imaging cameras show heat changes that can mean electrical faults. You can use machine learning tools to help you understand the images. These tools make it easier to find problems and plan repairs.

Note: Good images and smart software help you make better choices.

Technical Limitations

Drones and imaging tools can have some limits. Battery life can stop drones from flying long. Weak signals in some places can make it hard to send images right away. Heavy sensors can make drones fly for less time. You can fix many of these problems by using lighter imaging modules and planning your flights well. Newer drones have better batteries and stronger data links, so you can cover more area and get better images.

Real-World Examples

Utility Company Case Studies

Utility companies use drones with thermal imaging to check power lines. One team checked 5,500 towers in only 183 days. Before drones, this job took 1,183 days to finish. Each tower took about 45 minutes to inspect. This made the work 80% faster than before. The team used thermal and UV imaging to find problems. About 40% of towers showed signs of Corona discharge. This issue can cause costly repairs if not found early. These results show drones and imaging tools make inspections quicker and better.

Notable Inspection Outcomes

Utility companies see many good things after using drones with thermal imaging. Here is a table that lists some main results:

Outcome | Description |

|---|---|

Safety Improvement | Drones make inspections safer and keep workers away from danger. |

Cost Savings | Drones help save money and use resources better. |

Efficiency | Inspections take less time, so projects finish faster. |

Data Quality | Drones give more accurate data for better planning. |

Condition-Based Maintenance | Drones help check equipment more often and fix problems sooner. |

Drones help you stay safe, spend less, and get better data for your power lines.

Best Practices

You can follow some easy steps to get the best results from drones and thermal imaging:

Use drones with thermal sensors to find damaged insulators and hot connectors. This helps stop outages and keeps your team safe.

After storms, send drones out fast to look for downed lines or blockages.

Plan regular drone checks to scan many towers much faster than old ways.

Collect high-quality images and LiDAR data to make a digital record. This helps you manage equipment and plan repairs.

Set up drones to fly on their own when faults happen. This helps you find and fix problems faster.

Tip: Drones and thermal imaging together let you see your power lines clearly and fix small problems before they get big.

You can see how drone thermal cameras make power line checks better. These cameras help you find hot spots and bad connections. You do not have to do dangerous checks by hand. This saves you both time and money. Utility companies use these cameras to stop power loss and spend less. Imaging works with AI to help you understand problems and fix them smarter. Imaging will keep getting better, so power line checks will be safer and more dependable.

Drones help finish checks faster and for less money.

Imaging helps you find issues before things break.

Imaging makes checks safer and gives better data.

FAQ

What can you find with a drone thermal camera during power line inspections?

You can find hot spots and broken wires. Drones with thermal imaging show problems early. This helps you fix things before power goes out.

How does thermal imaging for electrical maintenance improve safety?

Thermal imaging keeps you away from live wires. You check equipment from far away. This lowers the chance of getting hurt.

Can you use drones for other types of thermal imaging surveys?

Yes, drones work for many thermal imaging jobs. You can look for leaks or check buildings. Drones can also scan roofs for heat problems.

Why is anomaly detection important in power line inspections?

Anomaly detection finds strange heat patterns. You can see faults that might cause trouble. Thermographic imaging helps you check for problems early.

What are the benefits of remote inspection with drones?

Remote inspection saves time and money. Workers stay out of dangerous places. Drones gather data fast and help keep equipment working well.

See Also

Using Vanadium Oxide Thermal Cameras for Effective Rescues

Guide to Utilizing Thermal Imaging for Rescue Operations in 2025

The Importance of Thermal Imaging Cameras in 2025

Best Reviewed AI Video Systems for Vehicles in 2025

Reliable CarPlay Adapters for RAV4 in Harsh Canadian Winters