When you do electrical work, you need safe tools. You also need tools that give correct results. The verytek ix2 air se wireless thermal camera is very sensitive. It works without wires and is easy to carry. This Industrial Thermal Camera helps you find electrical problems fast. With the verytek ix2 air se wireless thermal camera, you can check electrical parts. You can see temperature changes and record what you do. This camera helps you keep your work safe and easy. Use the verytek ix2 air se wireless thermal camera to do better electrical work.

Key Takeaways

Charge the Verytek IX2 AIR SE camera all the way. Change the settings to what you need. Connect it to your phone or tablet. This makes it easy to use.

Always follow safety rules before you start. Wear your safety gear. Turn off the power. Make sure your work area is clean and bright.

Use the camera to scan electrical panels slowly. Move the camera steady and do not rush. Look for hot spots. Hot spots can mean loose wires or too much power.

Take clear thermal pictures of problem spots. Also take pictures of normal panels. This helps you see changes later. It also helps with repairs and reports.

Take care of your camera to keep it working well. Clean the lens often. Charge the battery when needed. Update the app to make sure it works right.

Setup

Unboxing

Start by opening the box carefully. Inside, you will find the verytek ix2 air se wireless thermal camera, a USB charging cable, a quick start guide, and a back clip. Check that all items are present. The camera feels light in your hand. It weighs only 130 grams. The compact size makes it easy to carry to any job site. The camera has a strong case. This gives you protection from dust and water with its IP54 rating. You also get drop protection up to 2 meters. This means the camera can handle tough work environments.

Tip: Always keep the box and packaging. You can use them for extra protection when you travel.

Charging

Before you use the camera, charge it fully. Use the USB cable that comes in the box. Plug one end into the camera and the other into a power source. A small light on the camera shows when it is charging. Wait until the light turns green. This means the battery is full. A full charge gives you about two hours of use. This helps you finish your inspections without stopping.

Initial Settings

Turn on the camera by pressing the power button. The screen lights up. Follow the guide on the screen to set the language and date. Connect the camera to your phone or tablet if you want to use the app. The app lets you update the camera and change settings. You can also set up Wi-Fi or Bluetooth for easy image sharing. Adjust the settings to match your needs. The camera is now ready for your first inspection.

Wireless Connection

Wi-Fi and Bluetooth

You can connect your camera to your phone or tablet using Wi-Fi or Bluetooth. First, turn on the camera. Open the settings menu. Choose Wi-Fi or Bluetooth. On your smart device, go to the Wi-Fi or Bluetooth settings. Look for the camera’s name in the list. Tap to connect. If you use Wi-Fi, you get fast image transfer. Bluetooth works well for simple connections. You can also use a USB cable if you want a direct link. This gives you more options for different jobs.

Tip: Always check that your smart device’s Wi-Fi or Bluetooth is on before you try to connect.

App Integration

Download the official app on your phone or tablet. The app lets you control the camera and view images in real time. You can also use the app to update the camera with OTA (over-the-air) upgrades. This keeps your camera up to date with new features. The app helps you analyze images both online and offline. You can mark hot and cold spots, draw lines, and use different color palettes. The app also lets you send images to others or save them for reports.

Key App Features:

Real-time image viewing

Offline image analysis

OTA upgrades

Easy image sharing

Troubleshooting

If you have trouble connecting, try these steps:

Restart the camera and your smart device.

Make sure both devices have enough battery.

Check that you selected the right Wi-Fi or Bluetooth network.

Move closer to the camera if the signal is weak.

Update the app to the latest version.

If you still cannot connect, use the USB cable as a backup. The verytek ix2 air se wireless thermal camera gives you many ways to stay connected and work smoothly.

Maintenance Preparation

Safety

You need to think about safety first. Always wear the right gear. Put on gloves, safety glasses, and rubber-soled shoes. Do not touch live wiring or circuits. Turn off the power at the main panel. Use a lockout tag to show the power is off. Have a safety standby operator close by. This person can help if there is an emergency. These steps keep you and others safe.

Checklist for Electrical Safety:

Wear personal protection equipment.

Turn off the main panel.

Use lockout tags.

Keep a safety standby operator close.

Never touch exposed wiring or circuits.

Environment

Get your work area ready before you start. Clean up water, dust, and clutter from the floor. Make sure the lights are bright so you can see well. Keep your tools and the Verytek IX2 AIR SE Wireless Thermal Camera nearby. Only let trained operators in the work area. Put up signs to mark the work zone. This keeps other people away. Good preparation helps stop accidents and keeps everyone safe.

Equipment Check

Look at all your equipment before you begin. Check the camera for any damage. Make sure the battery is charged. Test the camera by scanning a panel or outlets. Watch for damaged wires or loose parts. Check all circuits and outlets for heat. Use the camera for condition monitoring and inspections. If you see damaged wires or hot spots, tell someone right away. This helps with corrective maintenance and keeps things safe. Operators should always follow front line maintenance steps to keep everything working.

Task | What to Check | Who Checks |

|---|---|---|

Camera | Battery, lens, settings | Operators |

Wiring & Circuits | Damage, heat, loose parts | Operators |

Outlets & Panel | Signs of wear, overheating | Operators |

Tip: Always finish your preventive maintenance tasks before starting new work. This keeps your electrical system safe and working well.

Electrical Inspections

Scanning

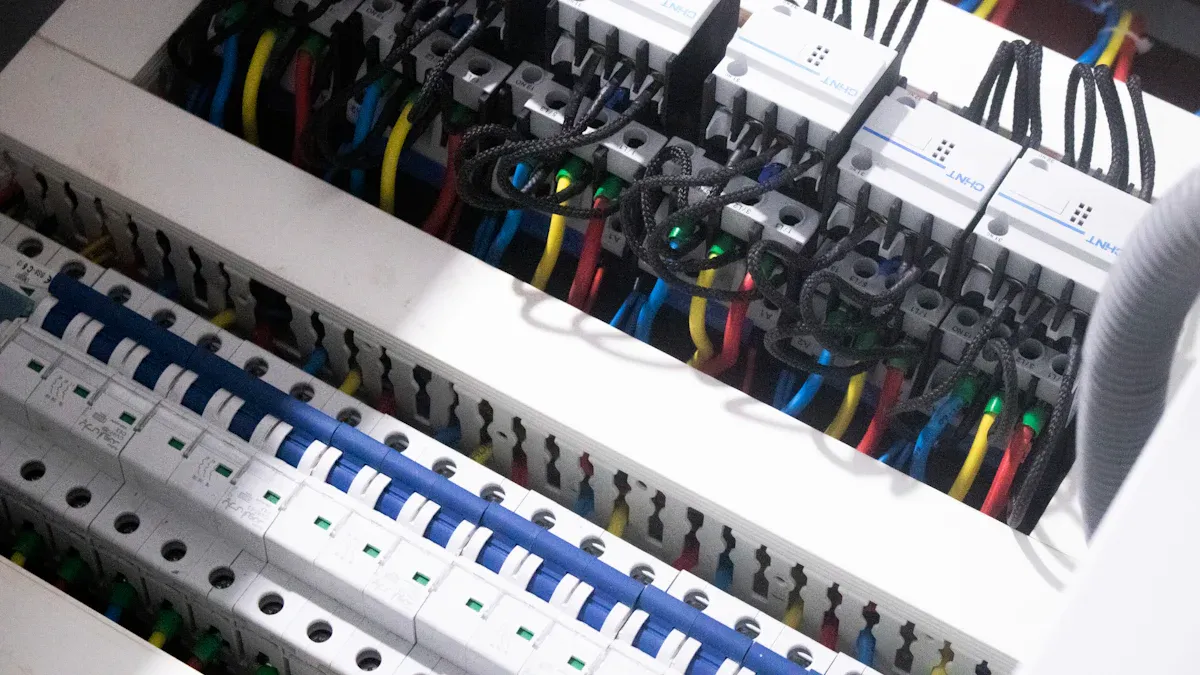

Start your inspection by looking at the electrical panel. Hold the Verytek IX2 AIR SE Wireless Thermal Camera in your hand. Stand in front of the panel and point the camera at it. Move the camera slowly from side to side. Make sure you scan every part of the panel. Look at the wiring, outlets, and circuit breaker. Watch the screen for any strange heat spots. Operators need to check each wire and connection. Scan the top, bottom, and sides of the panel. Do not skip any wiring or circuits.

Tip: Keep your hand steady and hold the camera at the right distance. This helps you get clear pictures and correct temperature readings.

You can use the camera to scan panels in many places. Check main panels, subpanels, and control panels. Scan outlets and wiring behind covers too. Operators should also scan circuits that use a lot of power. Doing regular inspections helps you find problems early. This way, you can stop failures and keep your electrical system safe.

Performance metrics show why scanning is important:

You find strange heat in wiring and panels before damage happens.

You stop fire risks by finding parts that get too hot.

You fix problems before they stop your work.

You help your electrical system work better.

You make panels and wiring last longer by stopping overheating.

You save energy by fixing bad connections.

Here is a real example. In a factory, operators used thermal scanning on a panel. They found a loose wire connection. They fixed it before it caused a problem. This stopped downtime and kept the work going.

Hotspot Detection

Hotspot detection is very important for electrical inspections. When you scan a panel, look for places that are hotter than others. Hotspots can mean loose wires, overloaded circuits, or damaged wiring. The Verytek IX2 AIR SE Wireless Thermal Camera helps you see these hot spots easily. The camera is very sensitive and shows small temperature changes.

Operators should check every circuit and outlet for hotspots. You can use different color palettes to make hot areas stand out. Try the “Iron,” “Rainbow,” or “White Hot” palettes. Each palette shows heat in a different way. Pick the one that helps you see changes best.

Note: Make sure the camera is focused and at the right distance. This helps you find small hotspots.

Studies show that thermal imaging with correction algorithms gives good temperature readings. These readings help you find faults in panels and wiring. Machine learning systems using thermal images can sort faults with less than 10% error. This means you can trust the camera to find real problems in your circuits and wiring.

Operators should always look for hotspots during inspections. Hotspots can mean loose connections, overloaded circuits, or damaged wires. If you find a hotspot, mark it for repair. This keeps your electrical system safe and working well.

Image Capture

After you find a hotspot or problem, you need to take a picture. The Verytek IX2 AIR SE Wireless Thermal Camera lets you save thermal images with one click. Point the camera at the panel, wiring, or outlet. Make sure the hotspot or problem is in the middle of the screen. Press the capture button. The camera saves the image for you to look at later.

Operators should take pictures of all problem areas. Take pictures of panels, circuits, outlets, and wiring. Save pictures of normal panels too. This gives you a record for future checks. You can compare pictures over time to see if a problem gets worse.

Tip: Use the app to write notes for each image. Write down the panel name, circuit number, and what you found.

Thermal image capture is reliable and works well. Studies show that thermal images match other inspection methods. For example, electroluminescence imaging of solar panels finds cracks that also show up as hotspots in thermal images. This means you can trust the camera to show real problems in panels and wiring. The app helps you find and mark hotspots quickly. You do not need to turn off the power to take pictures. The camera works safely on live panels and circuits.

Operators should use image capture for all maintenance work. Save images for reports and share them with your team. This helps everyone know the condition of the electrical system. Good image records make future inspections easier and more accurate.

Task | What to Capture | Why Capture |

|---|---|---|

Panel Scan | Whole panel, all wiring | Find hidden issues |

Hotspot Detection | Hot areas, damaged wiring | Plan repairs |

Outlet Inspection | Outlets, connections | Check for overload |

Circuit Check | Each circuit, connections | Track changes |

Reminder: Always check your images after each inspection. Make sure you took pictures of all panels, circuits, outlets, and wiring.

Results and Reporting

Image Analysis

After you finish your inspection, look at the thermal images you took. The Verytek IX2 AIR SE Wireless Thermal Camera and its app help you do this fast. You can see the hottest, coldest, and middle spots in each image. The app lets you draw lines, add boxes, and mark important places. This helps you find electrical problems more easily.

Check for spots that are hotter than normal. These hot spots can mean loose wires, too much power, or broken parts. The app’s templates help you compare pictures and see changes over time. You can use seven color palettes to make temperature changes stand out.

A confusion matrix from a 10-fold test on 2,100 images shows high accuracy for finding electrical problems. Most results match the real issues.

A CNN model found almost all defect images, with only two mistakes.

When you use image analysis, you can link heat changes to real drops in electrical work. For example, you might see a 1.7% drop in current or a 5.5% drop in power when you find a problem.

You can trust the camera and app to help you find and understand electrical problems. This makes your maintenance work better and more reliable.

Common Issues

Thermal imaging helps you find many common electrical problems. You might see hot spots, loose wires, or circuits with too much power. Sometimes, you will notice broken wires or parts that get too hot. These problems can cause fires or equipment to stop working if you do not fix them.

You can use image quality tools to check if your thermal images are clear. Tools like BRISQUE, NIQE, and PIQE help you see if your images have blur or noise. These tools match what people see when they look at the images. They help you find problems even if you do not have another image to compare.

Thermal cameras also help you find problems in other jobs. You can use the camera for HVAC checks, circuit board checks, and solar panel checks. The camera’s high sensitivity and clear images make it good for many tasks.

Tip: Always check your images after each inspection. Clear images help you find and fix electrical problems faster.

Saving and Sharing

After you look at your images, you need to save and share your results. The app lets you store images and notes for each inspection. You can export reports with thermal images, temperature graphs, and comments. This makes it easy to show your findings to your team or clients.

Saving and sharing images is important for preventive maintenance. When you keep good records, you can track changes and plan repairs before things get worse. Professional reporting lets you add images, graphs, and comparison views. This helps everyone understand the electrical problems and decide what to do next.

Studies show that sharing thermal images helps people take action. For example, when people see images of their own equipment, they are more likely to fix problems. Reports with clear images and notes help people talk and make better choices.

Task | What to Save/Share | Why It Matters |

|---|---|---|

Inspection Images | Thermal images, notes | Track changes, plan repairs |

Reports | Images, graphs, comments | Share with team or clients |

Maintenance Records | All inspection data | Improve future work |

Camera Care

You need to take care of your Verytek IX2 AIR SE Wireless Thermal Camera to keep it working well. Always clean the lens with a soft cloth. Store the camera in a dry place when you finish your work. Check the battery before each use. Charge the camera fully so you do not run out of power during inspections.

Look at the camera for damage after each job. Make sure the lens is clean and the buttons work. Use the back clip or a tripod to keep the camera safe while you work. Update the app and camera firmware often. OTA upgrades give you new features and better performance.

You can use the camera for many types of maintenance, not just electrical work. Try it for HVAC systems, machine checks, and building surveys. Good camera care means you get correct results every time you use it.

Reminder: Regular care of your camera helps you avoid problems and keeps your inspections correct.

The Verytek IX2 AIR SE Wireless Thermal Camera helps make your electrical work safer. It also helps you get more accurate results. Set up the camera carefully and always follow safety rules. Scan every panel and wire to find problems early. Save your images and share them for better reports. Take care of your camera after each inspection. Use the camera’s special features to do better electrical maintenance. You can also use it for other kinds of maintenance.

FAQ

How do you update the Verytek IX2 AIR SE Wireless Thermal Camera?

You can update your camera using the official app. Open the app, connect your camera, and check for OTA (over-the-air) updates. Follow the on-screen steps. Updates add new features and improve performance.

What should you do if the camera does not connect to your phone?

First, restart both your camera and phone. Make sure Wi-Fi or Bluetooth is on. Move closer to the camera. Try using the USB cable if wireless does not work. Check the app for updates.

Can you use the camera on live electrical panels?

Yes, you can use the camera on live panels. Always follow safety rules. Wear protective gear and keep your hands away from exposed wires. The camera lets you inspect without touching any parts.

How do you clean and store the camera after use?

Use a soft, dry cloth to clean the lens and body. Store the camera in a dry, safe place. Charge the battery before putting it away. Keep the camera in its case to protect it from dust and damage.

See Also

Using Thermal Imaging Cameras Effectively For Rescue Missions 2025

Vanadium Oxide Thermal Cameras Enhancing Rescue Operations Today

The Importance Of Thermal Imaging Cameras In 2025